-

2025 Global Steel Cord Conveyor Belt Market Outlook: Growth Drivers and Regional Trends

Posted on July 2.202l bytemplatemonsterThe global market for steel cord conveyor belts is ente […]

Read More -

Elin Conveyor Steel Cord Conveyor Belts: Trusted by Southeast Asia’s Mining Industry

Posted on July 2.202l bytemplatemonsterWhen it comes to heavy-duty material transportation in […]

Read More -

How to Repair a Damaged Rubber Conveyor Belt?

Posted on July 2.202l bytemplatemonsterRubber conveyor belts are essential components in indus […]

Read More -

Innovative Steel Cord Rubber Conveyor Belt Revolutionizes Material Handling

Posted on July 2.202l bytemplatemonsterIn a significant development for the material handling […]

Read More -

Detailed technical specifications for Elin rubber conveyor belts

Posted on July 2.202l bytemplatemonsterElin rubber conveyor belts are commonly used for variou […]

Read More -

What is white rubber conveyor belt?

Posted on July 2.202l bytemplatemonsterNowadays, white rubber conveyor belts have become one of the main auxiliary equipment in industrial production. Their advantages are compact structure, easy use, low price, etc.

Read More -

What is a high-angle conveyor belt?

Posted on July 2.202l bytemplatemonsterA high-incline conveyor belt is a device that uses a special inclined design to transport materials from one place to another. Its advantage is that it can significantly reduce shipping time and costs.

Read More -

How to configure steel cord conveyor belt from ELIN Conveyor?

Posted on July 2.202l bytemplatemonsterWhether in the production process or in the logistics process, large-angle edge conveyor belts can have very good results. It can adjust the inclination angle of the large-angle rib conveyor belt to reduce friction during the transportation of materials, thus improving the efficiency of the entire transportation process.

Read More -

How long is the service life of a steel cord conveyor belt and what is its main function?

Posted on July 2.202l bytemplatemonsterWith the development of the economy, people have higher and higher requirements for product quality.

Read More

Questions

Frequently Asked

Questions

Belted for success: find answers to your conveyor needs!

2025 Global Steel Cord Conveyor Belt Market Outlook: Growth Drivers and Regional Trends

The global market for steel cord conveyor belts is entering 2025 amid steady demand from heavy industries and growing interest in higher-performance, long-distance conveying solutions. Market estimates vary by source, but several recent reports indicate a multi-billion-dollar market for steel-cord and other heavy-duty conveyor systems, with double-digit variability in forecasts depending on scope and definitions.

Key growth drivers

Mining remains the single largest and most consistent driver of steel cord belt demand. As mines push for larger scale, higher throughput, and longer overland conveyors, steel cord constructions — prized for superior tensile strength and limited elongation — are the preferred choice for long-haul, high-tension applications. Renewed project spending in base metals (copper, iron ore), as well as expansions in bulk commodity handling, is keeping replacement and new-install pipelines healthy.

Port modernization and bulk material handling upgrades are another major contributor. Automation projects at terminals, increased vessel sizes, and a focus on throughput efficiency have translated into requirements for more robust belt solutions that minimize downtime and maintenance cycles — areas where steel cord belts offer lifecycle advantages. At the same time, manufacturers and end-users are beginning to pair belts with condition monitoring and IoT systems to enable predictive maintenance and reduce unplanned outages.

Infrastructure, cement, and steel sectors also sustain demand where heavy loads, high temperatures, or hostile environments dictate higher-spec belt constructions. Across these segments, lifecycle cost (LCC) analysis — factoring in downtime, splice reliability, and maintenance — is shifting procurement decisions away from short-term low-cost options toward higher-performance steel cord products.

Regional trends

Asia-Pacific continues to dominate both consumption and production capacity for steel cord belts, driven by large mining markets (China, India, Indonesia, Australia), rapid port expansion, and substantial infrastructure investment. Several market studies place APAC as the largest regional market and the fastest growing, a pattern expected to persist through the late-2020s as new projects come online and existing transport networks are upgraded.

North America and Latin America remain important markets, particularly for heavy mining projects and midstream material handling; Latin America’s extensive copper and lithium activity fuels specific demand pockets. Europe shows steady, replacement-driven demand, often with a higher emphasis on regulatory compliance and environmental measures that affect procurement specifications.

Competitive landscape and supply considerations

The supplier base remains a mix of established global brands and regional manufacturers. Traditional tire and conveyor specialists and diversified industrial firms continue to compete on technical performance and aftermarket service, while lower-cost producers from Asia and Turkey pressure the market on price and delivery. Buyers are increasingly weighing total-cost arguments and vendor service footprints — especially for long projects in remote locations where spares and rapid service are critical.

Risks and near-term outlook

Key risks include volatility in raw material prices (steel and rubber compounds), supply-chain disruptions, and the potential for trade or tariff actions that can alter cost competitiveness. Conversely, the integration of smart monitoring, sustainability demands (recyclable compounds, lifecycle emissions), and a global push for higher throughput create upside for steel cord solutions. Recent market studies predict moderate growth for the broader conveyor sector and continued tailwinds for steel-cord segments that serve long-distance, heavy-duty needs.

Implications for suppliers and buyers

For manufacturers and exporters — especially companies targeting mining and port projects — the recommendations are clear: emphasize proven lifecycle performance, strengthen global service and splicing capabilities, and adopt condition-monitoring partnerships. For buyers, rigorous LCC comparisons and supplier service audits will deliver the best value as the sector modernizes through 2025 and beyond.

Elin Conveyor Steel Cord Conveyor Belts: Trusted by Southeast Asia’s Mining Industry

When it comes to heavy-duty material transportation in demanding environments, steel cord conveyor belts are the backbone of efficiency and reliability. At Elin Conveyor, a leading Chinese manufacturer with over two decades of expertise, we specialize in engineering high-performance conveyor belts tailored to global industries. Today, we’re excited to share how our solutions are transforming mining operations in Southeast Asia, backed by a recent success story from a valued client.

Why Choose Elin Conveyor Steel Cord Belts?

Our belts are built to endure extreme conditions while maximizing productivity:

-

Unmatched Durability: Reinforced steel cords with tensile strengths exceeding 4,500 N/mm² ensure resistance to impact, abrasion, and elongation.

-

Customized Design: Adaptable to conveyor lengths (up to 30 km) and load capacities, ideal for rugged mining terrains.

-

Safety Compliance: Flame-retardant and anti-static properties meet international standards like ISO 340 and DIN 22131.

A Success Story: Partnering with a Southeast Asian Mining Leader

In early 2024, a prominent mining company from Indonesia approached Elin Conveyor seeking a reliable solution for their high-capacity coal transportation system. After evaluating multiple suppliers, they chose to visit our state-of-the-art factory in Shandong, China, to witness our production process firsthand.

Key Highlights of Their Visit:

-

Factory Tour: The client inspected our advanced steel cord weaving technology, vulcanization lines, and rigorous quality control protocols.

-

Technical Collaboration: Our engineers worked closely with their team to customize belt specifications, including ST6300 strength grade and a 1,800 mm width to handle 5,000 tons/hour throughput.

-

Trust Through Transparency: Open discussions about material sourcing, testing certifications, and after-sales support solidified their confidence in our partnership.

The Result:

Within six weeks of the factory visit, Elin Conveyor delivered and installed the steel cord conveyor belts. The client reported a 30% reduction in downtime and seamless performance in their 12-kilometer mining conveyor system, even in humid, high-temperature conditions.

Tailored Solutions for Unique Challenges

Every mining operation has distinct needs. For our Indonesian client, we addressed:

-

Corrosion Resistance: Added a specialized rubber coating to protect against moisture and acidic materials.

-

Long-Distance Efficiency: Optimized belt joints to minimize energy loss across the 12-km span.

-

Quick Turnaround: Prioritized production scheduling to meet their tight project timeline.

Our Commitment to Quality

At Elin Conveyor, quality isn’t just a promise—it’s embedded in our process:

-

Raw Material Sourcing: Premium steel cords and rubber compounds from certified suppliers.

-

In-House Testing: Every batch undergoes stress tests, adhesion checks, and flame resistance trials.

-

Global Reach: Over 500 successful installations across 30+ countries, from Australia to South America.

Why Southeast Asia Chooses Elin Conveyor

The region’s booming mining and logistics sectors demand partners who understand local challenges. Our on-ground technical support, fast delivery via ASEAN ports, and competitive pricing make us the preferred choice for projects in:

-

Indonesia (coal, nickel)

-

Vietnam (cement, aggregates)

-

Malaysia (palm oil, mineral processing)

Join Our Growing List of Satisfied Clients

Whether you’re upgrading an existing system or designing a new conveyor network, Elin Conveyor combines innovation with practicality. Let us help you:

-

Cut operational costs with longer belt lifespan.

-

Boost safety with reliable, low-maintenance solutions.

-

Scale efficiently with belts designed for future expansions.

Visit our factory or contact our team today to discuss your project requirements. Together, we’ll keep your operations moving forward.

Elin Conveyor – Engineering Excellence, Delivered.

How to Repair a Damaged Rubber Conveyor Belt?

Rubber conveyor belts are essential components in industries such as mining, manufacturing, construction, and logistics. They facilitate the efficient movement of materials, but over time, they can suffer from wear and tear, leading to damage such as cuts, tears, or holes. Repairing a damaged conveyor belt is crucial to minimize downtime, reduce costs, and maintain productivity. This guide will walk you through the steps to effectively repair a damaged rubber conveyor belt, whether the damage is minor or major.

**Step 1: Assess the Damage**

Before starting any repair, it’s important to evaluate the extent of the damage. Conveyor belt damage can range from small cuts and abrasions to large tears or punctures. Here’s how to assess the damage:

– **Identify the Type of Damage:**

– **Cuts or Tears:** These are common in heavy-duty applications like mining.

– **Holes or Punctures:** Often caused by sharp objects or improper loading.

– **Edge Damage:** Occurs when the belt rubs against the frame or misaligns.

– **Belt Slippage or Misalignment:** This may indicate structural issues or improper tensioning.

– **Determine the Severity:**

– **Minor Damage:** Small cuts, superficial wear, or small holes.

– **Major Damage:** Large tears, deep punctures, or structural damage.

Understanding the type and severity of the damage will help you choose the right repair method.

### **Step 2: Gather the Necessary Tools and Materials**

To repair a conveyor belt, you’ll need the following tools and materials:

– **Tools:**

– Utility knife or belt cutter

– Sandpaper or grinding tool

– Clamps or vulcanizing press

– Heat gun or vulcanizing machine

– Cleaning solvent (e.g., acetone)

– **Materials:**

– Rubber repair patches or strips

– Adhesive (cold bonding cement or vulcanizing solution)

– Fabric reinforcement (if needed for added strength)

Having the right tools and materials on hand will ensure a smooth and efficient repair process.

**Step 3: Prepare the Damaged Area**

Proper preparation is key to a successful repair. Follow these steps:

1. **Clean the Area:**

– Remove dirt, grease, and debris using a cleaning solvent like acetone.

– Ensure the surface is completely dry before proceeding.

2. **Trim the Damaged Edges:**

– Use a utility knife to cut away frayed or uneven edges.

– Create a smooth, clean surface for the repair.

3. **Sand the Surface:**

– Lightly sand the damaged area to improve adhesion.

– Remove any loose particles with a clean cloth.

**Step 4: Apply the Repair Solution**

The repair method will depend on the severity of the damage:

**For Minor Damage (Small Cuts or Holes):**

1. Apply a layer of cold bonding cement to the damaged area.

2. Place a rubber repair patch over the damaged area.

3. Use a roller to remove air bubbles and ensure proper adhesion.

4. Allow the adhesive to cure as per the manufacturer’s instructions.

**For Major Damage (Large Tears or Structural Issues):**

1. Use a vulcanizing solution to bond the damaged edges.

2. Place a rubber strip or patch over the damaged area.

3. Use a vulcanizing press or heat gun to activate the bonding process.

4. Allow the repair to cool and cure completely.

**Step 5: Reinforce the Repair (if Necessary)**

For high-tension areas or severe damage, reinforcement may be required:

– Add fabric reinforcement for added strength.

– Apply an additional layer of adhesive and rubber patch over the reinforcement.

– Ensure the reinforcement is evenly distributed and securely bonded.

**Step 6: Test the Repair**

Once the repair is complete, it’s important to test the conveyor belt:

– Run the belt at low speed to ensure the repair holds.

– Check for any signs of weakness or misalignment.

– Monitor the repaired area during initial operation to confirm its durability.

**Step 7: Preventive Maintenance Tips**

To avoid future damage and extend the lifespan of your conveyor belt, follow these preventive maintenance tips:

– **Regular Inspections:** Check the belt for signs of wear and tear, such as cracks, fraying, or uneven wear.

– **Prompt Repairs:** Address minor issues immediately to prevent them from escalating into major problems.

– **Proper Alignment:** Ensure the belt is properly aligned to prevent edge damage and slippage.

– **Training:** Train operators on proper belt handling and maintenance practices.

– **Cleaning:** Keep the belt and surrounding area clean to reduce the risk of damage from debris.

**Conclusion**

Repairing a damaged rubber conveyor belt is a cost-effective way to maintain operational efficiency and avoid costly replacements. By following the steps outlined above, you can effectively repair minor and major damage, ensuring your conveyor belt continues to perform at its best. Regular maintenance and prompt repairs will not only extend the lifespan of your belt but also minimize downtime and improve productivity.

Whether you’re dealing with a small cut or a large tear, having the right tools, materials, and knowledge is essential for a successful repair. By incorporating these practices into your maintenance routine, you can keep your conveyor belt running smoothly and efficiently for years to come.

Innovative Steel Cord Rubber Conveyor Belt Revolutionizes Material Handling

In a significant development for the material handling industry, Double Arrow has unveiled its cutting-edge steel cord rubber conveyor belt, set to redefine efficiency and durability in bulk material transportation. This new product results from research and development and aims to meet the increasing demands of various sectors, including mining, construction, and manufacturing.

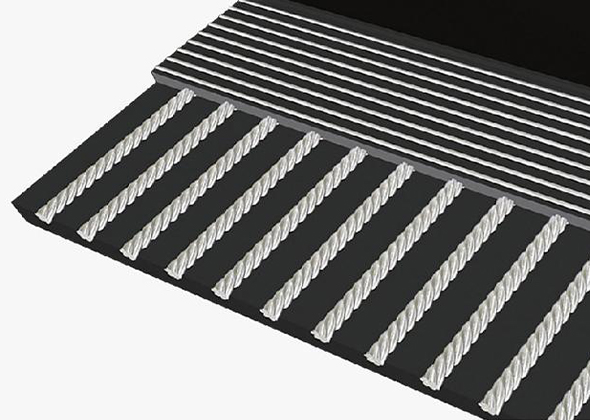

The steel cord rubber conveyor belt features a unique construction that combines high-strength steel cords with a specially formulated rubber compound. The steel cords provide excellent tensile strength, allowing the belt to carry heavy loads over long distances without stretching or breaking. Meanwhile, the rubber compound offers outstanding abrasion resistance, flexibility, and adhesion to the steel cords, ensuring a long service life even in harsh operating conditions.

One of the key advantages of this innovative conveyor belt is its ability to operate at high speeds. With a smooth and stable running surface, it can transport materials at rates far exceeding traditional conveyor belts, significantly increasing productivity. Additionally, the belt’s low energy consumption helps reduce operating costs, making it an environmentally friendly and cost-effective choice for businesses.

The new steel cord rubber conveyor belt has already attracted significant attention from industry experts and potential customers. A renowned analyst in the material handling field, commented, “This product represents a major leap forward in conveyor belt technology. Its combination of strength, durability, and high-speed performance has the potential to transform the way materials are transported in a wide range of industries.”

Double Arrow plans to launch the product globally in the coming months, backed by an extensive marketing and sales campaign. The company also offers comprehensive after-salesA support, including installation, maintenance, and training services, to ensure customers get the most out of their investment.

As industries continue to seek more efficient and reliable ways to handle bulk materials, the introduction of this innovative steel cord rubber conveyor belt comes at a crucial time. With its advanced features and performance capabilities, it is poised to become the go-to solution for businesses looking to optimize their material handling operations.

Detailed technical specifications for Elin rubber conveyor belts

Elin rubber conveyor belts are commonly used for various industrial applications due to their durability, flexibility, and resistance to wear and tear. They are typically designed for heavy-duty work in environments where high-performance conveyors are needed. Below are the detailed technical specifications that you might find for Elin rubber conveyor belts, though specific models may vary based on application:

- General Composition

- Cover Material:

- Natural rubber or synthetic rubber compounds, including chloroprene, nitrile, EPDM, or SBR, provide different resistance levels to heat, oil, abrasion, and chemicals.

- Carcass (Body):

- Multiple layers of textile fabric, steel cords, or a combination thereof.

- Common fabrics: Polyester, Nylon, Cotton, Aramid.

- Steel cord construction (for heavy-duty applications) provides high tensile strength and durability.

- Sidewalls and Edging:

- Reinforced with rubber or plastic to enhance the overall structure and prevent material spillages.

- Belt Width

- Standard Widths: 500 mm to 2400 mm or more.

- Custom widths can be made based on the client’s specific needs.

- Belt Thickness

- Typically ranges from 6 mm to 50 mm or more, depending on the application and load requirements.

- The thickness of the belt often includes the top and bottom cover as well as the carcass.

- Belt Strength (Tensile Strength)

- EP Fabric (Polyester/Nylon):

- Tensile strength typically ranges from 250 N/mm to 2000 N/mm (Newtons per millimeter) based on the application.

- Suitable for medium to heavy-duty use.

- Steel Cord Belts:

- Tensile strength: 1000 N/mm to 8000 N/mm, used for high-strength and long-distance applications.

- Steel cord belts offer higher resistance to elongation and breakage under high-load conditions.

- Elongation

- EP fabric belts: Elongation at break usually around 2% to 3%.

- Steel cord belts: Elongation at break is lower, usually around 0.5% to 1%.

- Belt Type

- Straight-warp conveyor belts: Suitable for applications requiring high durability and resistance to wear.

- Chevron or Cleated belts: Designed for inclined conveying of bulk materials, with various patterns like “V,” “U,” or “S” chevrons to prevent material slippage.

- Heat-resistant belts: Made with heat-resistant rubber compounds to handle temperatures up to 200°C or more.

- Oil-resistant belts: Resistant to oil and grease, commonly used in industries such as mining or steel processing.

- Cover Properties

- Abrasion Resistance: Abrasion-resistant rubber grades for extended lifespan in heavy-duty applications.

- Impact Resistance: Provides protection against heavy impacts from lumps of material or machinery.

- Oil and Chemical Resistance: Various formulations for protection against oils, acids, alkalis, and other chemicals.

- Heat Resistance: Some versions of Elin belts are designed for use in high-temperature environments (up to 180°C or higher).

- Flame Resistance: Belts with anti-flame additives, often used in mines, steel mills, and other hazardous environments.

- Weather and UV Resistance: Designed to resist degradation from exposure to sunlight and harsh weather conditions.

- Temperature Range

- Standard: -10°C to 60°C.

- Heat-resistant belts: Can withstand temperatures from 100°C to 180°C.

- Cold-resistant belts: Can function in temperatures as low as -40°C.

- Belt Surface

- Smooth Surface: For standard conveying applications.

- Rough/Patterned Surface: For inclined or steep-angle applications.

- Textured Surface: For improving grip on wet or slick materials.

- Edge Design

- Plain Edges: Common for standard applications.

- Sidewalls: Optional for inclined applications or where spillage is a concern.

- V-guides: Used for tracking belts to ensure the belt stays centered on the rollers.

- Belt Joining Methods

- Vulcanized Joints: Highly durable and commonly used for permanent and long-lasting joints.

- Mechanical Fasteners: Can be used for quicker installations and repairs, though these are less durable than vulcanized joints.

- Clipper and Alligator Joints: Common mechanical joining methods.

- Applications

- Mining: Conveying ores, rocks, and coal.

- Food Processing: Conveying foodstuffs, especially when oil or grease resistance is required.

- Agriculture: Transporting grains, fertilizers, or other agricultural products.

- Heavy Industry: Handling heavy materials such as metal ore, steel, and chemicals.

- Standards and Certifications

- Compliance with industry standards such as ISO 15236 (steel cord belts) and ISO 14890 (textile belts).

- DIN (German Industrial Standards) and RMA (Rubber Manufacturers Association) standards.

- Fire safety certifications (e.g., MSHA in the U.S. for mining applications).

These specifications are typical for high-performance Elin rubber conveyor belts, but they can vary based on specific models and customer requirements. If you have more specific needs, such as custom features or performance requirements, these can usually be met with tailored solutions.

What is white rubber conveyor belt?

Nowadays, white rubber conveyor belts have become one of the main auxiliary equipment in industrial production. Their advantages are compact structure, easy use, low price, etc.

- Production of white rubber conveyor belts

White rubber conveyor belts are made based on existing belts, mainly by adding steel wire ropes at both ends of the belts. White rubber conveyor belts are lifted from one end to the other by lifting machinery. White rubber conveyor belts have the advantages of smooth transmission, low noise, and easy maintenance. They are widely used in food, chemical, metallurgy, clothing, papermaking, printing, electronics, machinery, automobiles, aviation and other industries.

The method of using white rubber conveyor belts is very simple. Just pass the belt through the steel wire rope and then tie it up. White rubber conveyor belts can easily lift items without causing any damage to the items. White rubber conveyor belts are very practical items that can meet a variety of different lifting needs.

- Precautions for white rubber conveyor belts

A: Before installing the white rubber conveyor belt, it should be inspected to confirm that there is no obvious damage;

B: The installation requirements of the white rubber conveyor belt must comply with national standards;

C: When using the white rubber conveyor belt, pay attention to the running condition of the belt and deal with the problem in time;

D: Regularly maintain the white rubber conveyor belt to extend its service life.

At present, the application of white rubber conveyor belts in industrial production is becoming more and more extensive, and has achieved good results. We look forward to it bringing us more convenience in future development.

Nowadays, white rubber conveyor belts have become one of the main auxiliary equipment in industrial production. Their advantages are compact structure, easy use, low price, etc.

- Production of white rubber conveyor belts

The white rubber conveyor belt is made according to the existing belt, mainly by adding steel wire ropes at both ends of the belt. The white rubber conveyor belt is lifted from one end to the other by a lifting machine. The white rubber conveyor belt has the advantages of smooth transmission, low noise, and easy maintenance. It is widely used in food, chemical, metallurgy, clothing, papermaking, printing, electronics, machinery, automobile, aviation and other industries.

The method of using white rubber conveyor belt is very simple. Just pass the belt through the wire rope and then tie it up. White rubber conveyor belt can easily lift items without causing any damage to the items. White rubber conveyor belt is a very practical item that can meet various lifting needs.

- Precautions for white rubber conveyor belt

A: Before installing the white rubber conveyor belt, it should be checked to confirm that there is no obvious damage;

B: The installation requirements of white rubber conveyor belts must comply with national standards;

C: When using white rubber conveyor belts, pay attention to the operation of the belt and deal with problems in time;

D: Regularly maintain the white rubber conveyor belt to extend its service life.

At present, white rubber conveyor belts are more and more widely used in industrial production and have achieved good results. We look forward to it bringing us more convenience in future development.

What is a high-angle conveyor belt?

A high-incline conveyor belt is a device that uses a special inclined design to transport materials from one place to another. Its advantage is that it can significantly reduce shipping time and costs.

1: Concept of high-angle conveyor belt

The high-incline sidewall conveyor belt is a special conveyor belt with a large inclination angle that can effectively transport materials to the destination. Compared with traditional conveyor belts, large-angle conveyor belts have higher transportation efficiency and can significantly reduce production costs. With the development of the economy and the improvement of people’s living standards, large-angle conveyor belts will be more and more widely used in the fields of production and logistics, which will bring huge benefits to the development of our country’s economy.

2: Application of large-angle conveyor belts

High-angle conveyor belts are widely used in coal, metallurgy, chemical industry, building materials, cement, water treatment, food, feed, papermaking, printing, textile, shipbuilding, automobiles, motorcycles, electronics, machinery, rubber, plastics, non-metallic minerals and other industries department. The concept of high-angle conveyor belts

In the coal industry, large-angle conveyor belts can be used for slope transportation, mine lifting, underground transportation, coal bunker transportation, etc. In the metallurgical industry, large-angle conveyor belts can be used for internal transportation in smelting plants, foundry transportation, boiler room transportation, etc.

In the chemical industry, large-angle conveyor belts can be used for steam transportation, liquid transportation, powdery material transportation, etc.

3: Advantages of large-angle conveyor belts

High-angle conveyor belts have a series of advantages: First, they can effectively improve material transportation efficiency. Because the high-angle conveyor belt has a high transportation speed, it can significantly improve the material transportation efficiency. Secondly, high-angle conveyor belts have a long service life. Because of its excellent wear resistance and durability, its service life is relatively long. Thirdly, large-angle conveyor belts can withstand larger transportation loads. Because of its strong carrying capacity, it can withstand larger transportation loads. Finally, high-angle conveyor belts have good structural stability. Because it has good structural stability, it is not prone to failure during use.

4: Significance to my country’s economic development

The emergence of large-angle conveyor belts is of great significance to my country’s economic development. It can be said that it provides a more effective channel for my country’s industrial production and helps my country’s enterprises better achieve production efficiency. With the development of my country’s industry, more and more companies have begun to use large-angle conveyor belts. Moreover, because high-angle conveyor belts have high transportation efficiency and can significantly improve the production efficiency of enterprises, more and more companies are beginning to use high-angle conveyor belts. In addition, large-angle conveyor belts also have high durability and can run for a long time. Therefore, large-angle conveyor belts are of great significance to my country’s industrial production.

A high-incline conveyor belt is a device that uses a special inclined design to transport materials from one place to another. Its advantage is that it can significantly reduce shipping time and costs. In addition, it has high reliability and security.

How to configure steel cord conveyor belt from ELIN Conveyor?

Whether in the production process or in the logistics process, large-angle edge conveyor belts can have very good results. It can adjust the inclination angle of the large-angle rib conveyor belt to reduce friction during the transportation of materials, thus improving the efficiency of the entire transportation process.

1: Advantages of adjustable large-angle sidewall conveyor belts

The adjustable high-angle sidewall conveyor belt has the following advantages: 1. The angle of the high-angle sidewall conveyor belt can be adjusted to adapt to different application environments. 2. The large-angle edge conveyor belt can effectively prevent objects from falling and avoid damage to the goods. 3. The use of large-angle rib conveyor belts can significantly improve the operating efficiency of the production line. 4. High-angle sidewall conveyor belts can save energy and reduce production costs.

2: How to use

The method of using steel cord rubber conveyor belts is very simple, you just need to install it on your equipment. The installation method is also very simple, you just need to place it where you want the edge to be blocked.

3: How to configure

The adjustable high-angle sidewall conveyor belt mainly includes three parts: the conveyor belt assembly, the sidewall mechanism and the transmission mechanism. The adjustable high-angle sidewall conveyor belt needs to be configured according to the actual use environment and working conditions. The specific configuration method is as follows: 1. Select the appropriate conveyor belt model according to the characteristics of the conveyed materials and the requirements of the conveying route. 2. Select the appropriate side retaining mechanism according to the model and size of the conveyor belt. 3. Select the appropriate transmission mechanism according to the dimensions of the conveyor belt, sidewall mechanism and transmission mechanism. 4. Select the appropriate fixing method according to the configuration of the conveyor belt, sidewall mechanism and transmission mechanism. When configuring an adjustable high-angle sidewall conveyor belt, factors such as the characteristics of the conveyed materials, the requirements of the conveyor route, and the size and weight of the equipment must be taken into consideration, so that the appropriate conveyor belt model and configuration plan can be selected.

4: Application examples

When configuring the adjustable high-angle sidewall conveyor belt, customers can choose different types of conveyor belts according to their own requirements. For different types of materials, customers can choose different conveyor belts according to their own needs. Adjustable high-angle sidewall conveyor belts are mainly used for material transportation vertically or on slopes. The conveyor belt has high transportation efficiency and can transport materials to higher locations. For materials that need to be transported over longer distances, customers can choose different conveyor belts according to their own needs.

The advantages of large-angle sidewall conveyor belts have been widely used and achieved good results. We look forward to this high-quality product being more and more widely used in various fields in the future, bringing more convenience to people’s lives and work.

How long is the service life of a steel cord conveyor belt and what is its main function?

With the development of the economy, people have higher and higher requirements for product quality. Especially in the machinery industry, the requirements for product quality are even more stringent. Therefore, in the process of producing machinery, it is very necessary to select high-quality materials. Steel leather conveyor belt is one of them. It is composed of steel and conveyor belt, and has strong wear resistance and tensile strength. Therefore, it can withstand long-term use and high-speed movement during use.

1: What is the role of the high-angle conveyor belt?

The high-angle conveyor belt is one of the key components of the elevator, supporting the main operating load of the elevator. It works closely with multiple components such as the elevator frame, motor, hydraulic pump, etc., and is the key guarantee for the normal operation of the elevator.

2: What are the advantages of various high-angle conveyor belts?

A: Hard surface conveyor belt: made of hard material, with the advantages of high tensile strength, wear resistance, and not easy to deform.

B: Soft surface conveyor belt: made of soft material, with the advantages of wear resistance, impact resistance, and high tensile strength.

C: Composite conveyor belt: Made of a mixture of hard and soft materials, it has the advantages of wear resistance, impact resistance, and high tensile strength.

3: What are the precautions for purchasing high-angle conveyor belts?

When purchasing high-angle conveyor belts, you need to pay attention to the following points:

A: Choose a steel conveyor belt suitable for the elevator. Different types of steel conveyor belts are used in different elevators. Therefore, when purchasing, you need to ensure that the steel conveyor belt meets the requirements of the elevator.

B: Pay attention to the size of the steel conveyor belt. The size of the steel conveyor belt is related to the size of the elevator, so you need to ensure that the size of the steel conveyor belt meets the size requirements of the elevator.

C: Consider the use environment. High-angle conveyor belts may be affected by friction, impact or other external factors during use, so you need to consider their performance in the use environment.

D: Understand the service life of the steel conveyor belt. The service life of the steel conveyor belt is related to the service life of the elevator, so you need to understand the life of the steel conveyor belt during use.

E: Choose a suitable brand, such as ELIN Conveyor.

4: Fully understand before use

Before using a high-angle conveyor belt, be sure to fully understand its characteristics and usage rules to avoid unnecessary losses. Using high-quality machine steels and conveyor belts is essential to producing high-quality machinery. These components have excellent wear resistance and tensile strength and can withstand the test of time and rigorous use.